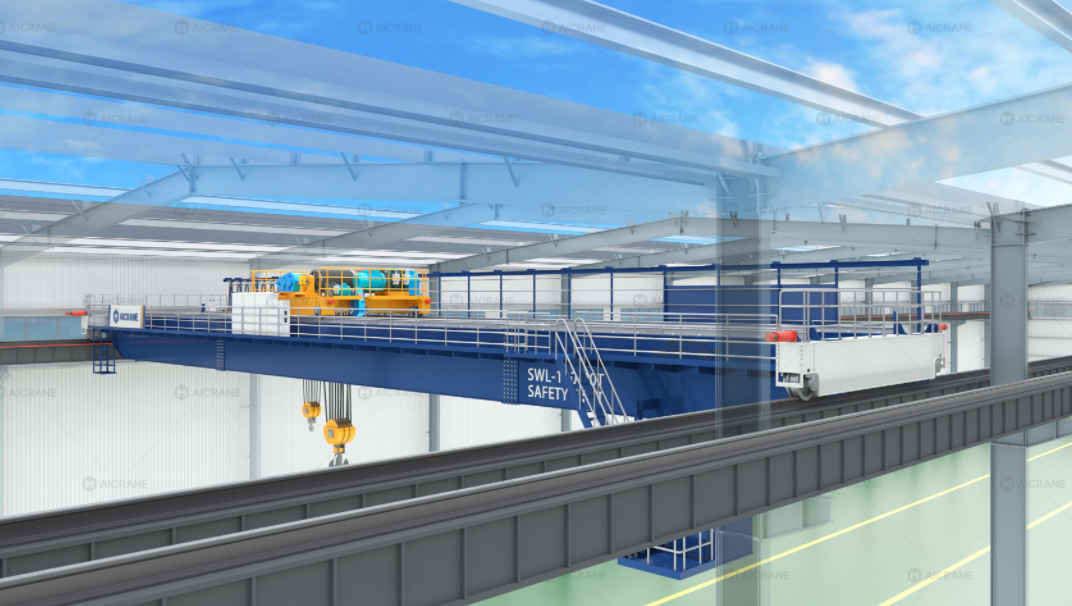

Electric Overhead Traveling (EOT) cranes are essential pieces of equipment in manufacturing, construction, warehousing, and material handling industries. Their ability to lift and transport heavy loads across a facility with precision makes them indispensable. However, operating these cranes safely and efficiently requires sophisticated control and safety systems. Among these, travel speed limiting systems play a crucial role in ensuring operational safety, protecting equipment, and improving workflow efficiency.

Understanding Travel Speed in EOT Cranes

Travel speed in an EOT crane for sale refers to the velocity at which the crane moves along its runway or tracks. This includes both the main girder movement (trolley movement along the crane bridge) and the bridge movement itself (crane movement along the runway rails). EOT cranes typically have variable speed controls to allow operators to adjust speed according to load, working conditions, and environmental factors.

While higher travel speeds can improve operational efficiency, excessive speed poses significant risks. Fast crane movement increases the likelihood of load sway, collisions, and operator errors. It also places additional stress on mechanical and structural components, potentially shortening equipment lifespan. To mitigate these risks, engineers implement travel speed limiting systems.

What Are Travel Speed Limiting Systems?

A travel speed limiting system is a safety and control mechanism integrated into an EOT crane to restrict the crane’s maximum allowable speed during operation. These systems are designed to prevent the crane from exceeding safe operating speeds under various conditions, reducing the likelihood of accidents and mechanical damage.

Modern travel speed limiting systems can be electronic, mechanical, or a combination of both, and they often integrate with the crane’s variable frequency drives (VFDs), programmable logic controllers (PLCs), and other automation systems.

Key Objectives of Travel Speed Limiting Systems

-

Operator Safety: Prevents accidents caused by excessive crane speed or sudden movements.

-

Load Stability: Minimizes load swing by controlling acceleration and deceleration.

-

Equipment Protection: Reduces wear and tear on motors, gearboxes, brakes, wheels, and rails.

-

Compliance: Ensures the crane adheres to national and international safety standards.

-

Operational Efficiency: Maintains smooth operation without unnecessary slowdowns in safe conditions.

Components of a Travel Speed Limiting System

Travel speed limiting systems are composed of several integrated components that work together to monitor and control crane movement:

1. Sensors and Encoders

Sensors detect the crane’s actual speed along the rails or runway. Encoders on motors measure the rotational speed, which is then translated into linear travel speed. These sensors continuously feed data to the control system, allowing real-time speed monitoring.

2. Programmable Logic Controller (PLC)

The PLC acts as the brain of the system. It receives input from sensors, compares the measured speed with pre-set speed limits, and sends control signals to the drive system to adjust the speed accordingly.

3. Variable Frequency Drive (VFD) Integration

Most modern EOT cranes are equipped with VFDs to allow smooth and precise speed control. When the PLC detects that the crane is approaching or exceeding the maximum safe speed, it signals the VFD to reduce power to the motors, thus slowing the crane down.

4. Mechanical Speed Limiters

In some cranes, particularly older models, mechanical speed limiters such as centrifugal governors or geared limiters are used. These devices physically restrict the maximum speed of the crane trolley or bridge, offering a failsafe if electronic systems fail.

5. Operator Interface

Crane operators need clear feedback about the speed limits. Control panels or HMI (Human Machine Interface) screens display current speed, set limits, and alerts, allowing operators to make informed decisions during operation.

Types of Travel Speed Limiting Systems

Travel speed limiting systems can vary depending on the crane design, application, and manufacturer. The main types include:

1. Fixed Speed Limiting

The crane is restricted to a pre-determined maximum speed, regardless of load or working conditions. This simple system is suitable for operations with uniform load sizes and minimal dynamic risk factors.

2. Load-Dependent Speed Limiting

In this system, the crane’s maximum travel speed changes according to the weight of the load. Heavier loads require slower speeds to reduce load sway and stress on the crane structure. Sensors measure the load weight, and the control system automatically adjusts travel speed.

3. Zone-Based Speed Limiting

Some facilities divide the crane runway into zones. Certain zones—such as areas near personnel, sensitive equipment, or tight corners—require reduced travel speed. The crane automatically adjusts its speed based on its current zone, enhancing safety in high-risk areas.

4. Dynamic Adaptive Speed Control

Advanced EOT cranes use real-time adaptive control algorithms to optimize speed based on multiple factors, including load, crane condition, wind speed (in outdoor facilities), and operator commands. This type of system provides the highest level of safety and efficiency but requires sophisticated electronics and software.

Benefits of Travel Speed Limiting Systems

Integrating travel speed limiting systems into EOT cranes brings multiple benefits for both operators and facility managers:

1. Enhanced Safety

Speed control directly reduces the risk of accidents. Limiting travel speed prevents collisions with structures or personnel, reduces load swing, and minimizes sudden movements that could destabilize loads.

2. Increased Equipment Longevity

By controlling acceleration, deceleration, and maximum speed, these systems reduce mechanical stress on motors, brakes, and structural components. This prolongs service life and reduces maintenance costs.

3. Improved Load Handling

Maintaining optimal travel speed ensures smoother operation. Controlled movement reduces the risk of damaging delicate or heavy loads, which is crucial for industries like manufacturing, warehousing, and material processing.

4. Regulatory Compliance

Many countries mandate speed control measures for cranes under national safety standards (e.g., OSHA in the United States, DGUV in Germany, ISO 9927). Implementing speed limiting systems helps companies meet legal requirements.

5. Operational Efficiency

While it may seem counterintuitive, speed limiting systems can improve overall efficiency. By preventing unsafe high-speed movements, they reduce downtime caused by accidents or load mishandling. Operators can also work more confidently, knowing the crane is operating within safe parameters.

Installation and Maintenance Considerations

Proper installation and regular maintenance of travel speed limiting systems are essential to ensure reliability:

-

Calibration

Sensors and controllers must be accurately calibrated to ensure that speed measurements and limits are precise. -

Testing

After installation, the system should undergo comprehensive testing under various loads and operating conditions to verify correct functionality. -

Routine Inspections

Periodic inspections of sensors, VFDs, mechanical limiters, and wiring ensure consistent performance and prevent failures. -

Software Updates

For electronic systems, software updates may be required to address bugs, improve algorithms, or integrate new operational features. -

Operator Training

Operators should be trained to understand speed limiting functions, warning signals, and emergency procedures.

Real-World Applications

Travel speed limiting systems are widely used across industries:

-

Steel and Aluminum Mills: Heavy duty overhead cranes handle molten metal and large coils. Speed limiting ensures safe transport without destabilizing heavy loads.

-

Automotive Manufacturing: Cranes move car bodies or assembly components, requiring precise speed control to avoid damage.

-

Warehousing and Logistics: Automated or semi-automated crane systems benefit from zone-based speed control, especially near personnel or storage racks.

-

Shipbuilding and Marine Industry: Cranes lift large ship components and equipment, where load swing could have catastrophic consequences if speeds are uncontrolled.

Future Trends

With advancements in automation and Industry 4.0, travel speed limiting systems are becoming more intelligent and integrated:

-

Predictive Algorithms: Using AI and machine learning, cranes can anticipate unsafe conditions and adjust speed proactively.

-

IoT Connectivity: Speed data can be transmitted to facility management systems for real-time monitoring and predictive maintenance.

-

Integration with Anti-Sway Systems: Combined speed and anti-sway controls allow cranes to move heavy loads faster without compromising stability.

Conclusion

Travel speed limiting systems are critical for safe, efficient, and reliable EOT crane operations. They protect operators, prevent equipment damage, and ensure compliance with safety standards while optimizing operational efficiency. By carefully selecting and maintaining these systems, businesses can maximize the performance of their cranes, reduce downtime, and protect both their workforce and valuable materials.

As crane technology evolves, travel speed limiting systems will become increasingly sophisticated, integrating predictive analytics, IoT monitoring, and adaptive controls, further enhancing safety and efficiency across all industries that rely on EOT cranes.