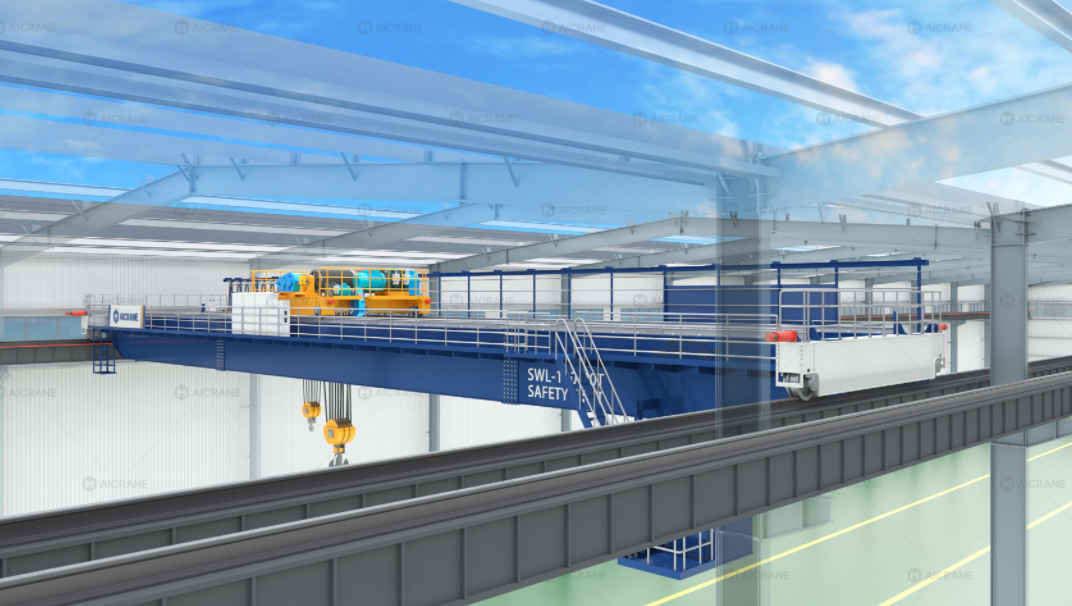

The integration of overhead cranes into steel structure factories is not merely a matter of installing heavy lifting equipment; it is a pivotal aspect that directly influences the design, functionality, and safety of the entire facility. Among the various factors that must be considered during the planning stage, the capacity of the overhead crane plays a central role. Overhead cranes are essential for lifting, moving, and positioning heavy materials such as steel beams, plates, and pre-fabricated components, and their specifications dictate many elements of factory layout and structural engineering. This article explores how the capacity of an overhead crane affects the design of a steel structure factory, including considerations for structural integrity, space planning, workflow efficiency, safety, and cost optimization.

1. Understanding Overhead Crane Capacity

Overhead crane capacity refers to the maximum weight that the crane can safely lift and transport. Capacities vary widely, from light-duty cranes handling 1–10 tons to heavy-duty gantry or bridge cranes capable of lifting 500 tons or more. In a steel structure factory, selecting the correct crane capacity is critical. A crane with insufficient capacity may slow production, cause frequent maintenance issues, or even risk catastrophic failure. Conversely, an over-specified crane may lead to unnecessary structural requirements and higher costs without delivering proportional benefits.

The crane capacity directly affects design parameters such as building height, column spacing, foundation strength, and crane runway configuration. Therefore, early-stage decisions regarding crane capacity are crucial for creating a factory layout that is safe, efficient, and cost-effective.

2. Structural Implications of Crane Capacity

One of the primary ways crane capacity affects factory design is through structural requirements. Higher capacity cranes impose greater loads on the supporting steel structure, which has significant implications for columns, beams, and foundations.

2.1 Column and Beam Design

For cranes handling heavy loads, the columns supporting the crane runway must be robust enough to withstand not only the vertical weight of the crane and lifted load but also dynamic forces caused by movement and acceleration. The beam spans that support the crane rails also need to be reinforced to prevent deflection, vibration, or structural fatigue over time. Engineers must account for the maximum lifting load, trolley weight, and potential side loads to ensure that deflection remains within safe limits.

For example, a factory planning to use a double girder 50 ton overhead crane may require columns spaced at 20–25 meters, reinforced beams with higher moment of inertia, and cross-bracing to resist lateral forces. In contrast, a 10-ton light-duty crane may allow for columns spaced at 30–40 meters and lighter beams, resulting in material cost savings.

2.2 Foundation Requirements

Crane capacity also dictates the type and size of foundations. Heavy-duty cranes generate significant vertical and horizontal loads that are transmitted through columns to the ground. Foundations must be designed to prevent settlement, tilting, or cracking, which could compromise crane operation and safety. High-capacity cranes may necessitate deep reinforced concrete footings or a raft foundation, while light-duty cranes might only require shallow isolated footings.

3. Building Height and Clearance

Another major design consideration influenced by crane capacity is building height. Higher capacity cranes often require taller hoisting mechanisms to lift large loads. The lifting height, combined with the height of the crane bridge and clearance for operator cabins, influences the overall height of the steel structure. Additionally, overhead clearance is necessary for safe handling and storage of materials.

For factories that handle long steel beams or large pre-fabricated modules, insufficient vertical clearance can restrict operations, reduce efficiency, and create safety hazards. Designers must carefully calculate the required headroom, which is typically determined by the sum of maximum load height, hook travel, and safety clearance.

4. Impact on Factory Layout and Workflow

Crane capacity has a direct influence on factory layout and workflow. Larger cranes can lift heavier loads and span longer distances, enabling more flexible material handling. This flexibility allows for optimized storage layouts, reduced travel times, and improved production efficiency.

4.1 Column Spacing and Work Zones

High-capacity cranes generally require more closely spaced columns to support the heavier load, which can affect the layout of workstations, assembly lines, and storage areas. Designers must balance structural requirements with operational needs, ensuring that the placement of columns does not obstruct workflows or limit access to machinery.

4.2 Multi-Crane Operations

In many steel structure factories, multiple overhead cranes operate simultaneously to handle large or irregular loads. The capacity of each crane affects the design of crane interference zones, overlapping spans, and synchronized operation protocols. Planning for adequate separation, collision prevention, and coordinated movement is crucial for safe and efficient operations.

5. Safety Considerations

The capacity of an overhead crane is a critical factor in ensuring workplace safety. Overloading a crane beyond its rated capacity can lead to mechanical failure, structural damage, or accidents involving personnel. Factory designers must incorporate safety margins into structural design, including:

-

Load Distribution: Ensuring that beams, columns, and foundations can handle peak loads without exceeding material stress limits.

-

Dynamic Forces: Accounting for acceleration, deceleration, and load swinging, which can create forces exceeding static weight calculations.

-

Emergency Systems: Designing adequate access and egress for operators, emergency stops, and protective barriers in high-load zones.

Safety standards and building codes often specify minimum requirements for crane integration, which must be adapted based on crane capacity.

6. Cost Implications

Crane capacity influences not only structural design but also overall project cost. Higher-capacity cranes require more robust steel structures, stronger foundations, and larger clearances, all of which increase material and construction expenses. Additionally, operational costs, including energy consumption and maintenance, typically rise with crane capacity.

Conversely, underestimating crane requirements can result in operational inefficiencies, delays, and retrofitting costs. Therefore, a careful balance between capacity, factory design, and budget is essential. Engineers often perform a cost-benefit analysis to determine the optimal crane capacity, taking into account expected loads, future expansion plans, and operational flexibility.

7. Integration with Automation and Technology

Modern steel structure factories increasingly incorporate automated systems, including CNC machinery, automated storage, and robotic material handling. The crane capacity determines the types of automation compatible with the facility. For instance, a high-capacity gantry crane equipped with automation features can handle heavy steel modules with precise positioning, enabling advanced assembly lines and reducing manual labor. Integrating crane capacity into digital factory layouts ensures smooth coordination between automated equipment and human operators.

8. Conclusion

The capacity of an overhead crane is a fundamental factor that shapes the design, functionality, safety, and cost of a steel structure factory. From structural requirements and foundation design to building height, column spacing, workflow optimization, and safety protocols, every aspect of factory design is influenced by the crane’s lifting capability. Engineers, architects, and factory planners must collaborate early in the design process to select the appropriate crane capacity, ensuring that the facility can handle present and future production needs efficiently and safely.

Choosing the correct overhead crane capacity is not simply a matter of lifting capability—it is a strategic decision that affects the structural integrity, operational efficiency, and overall cost-effectiveness of the steel structure factory. By carefully analyzing lifting requirements, load characteristics, and workflow considerations, factory designers can create a facility that maximizes productivity while maintaining the highest standards of safety and reliability.