Gantry cranes are essential lifting machines used in a wide range of industries, from shipyards and steel mills to precast concrete plants and logistics terminals. One of the most critical components determining a gantry crane’s operational efficiency is its traveling mechanism, which governs how the crane moves across the workspace. Broadly, gantry cranes can be classified based on their traveling system into rail-mounted gantry (RMG) cranes and rubber tyred gantry (RTG) cranes. While both types serve similar purposes—lifting and moving heavy loads—their traveling mechanisms, operational characteristics, and ideal applications differ significantly. Understanding these differences helps in selecting the right crane type for specific operational needs.

1. Overview of Gantry Crane Traveling Mechanisms

The traveling mechanism of a gantry crane consists of the components that allow the crane to move along a predefined path. This movement can be longitudinal along rails, or flexible over a yard using wheels and tires. The traveling system interacts closely with the hoisting and trolley mechanisms to ensure smooth load handling and precise positioning.

The main objectives of a gantry crane’s traveling mechanism include:

-

Providing stable movement: Ensuring the crane moves smoothly under load without excessive sway or vibration.

-

Facilitating precision positioning: Allowing the operator to place loads accurately within the operational area.

-

Supporting heavy loads: The system must bear the weight of the crane structure and lifted materials.

-

Ensuring safety and reliability: The mechanism should minimize derailment risks, slipping, or tipping.

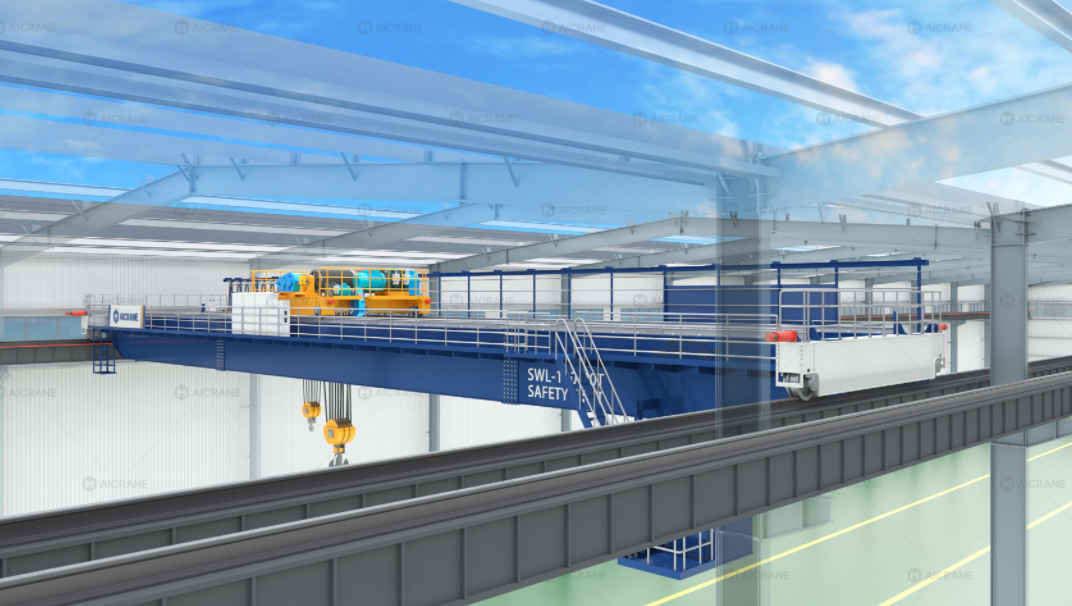

2. Rail-Mounted Gantry (RMG) Crane Traveling Mechanism

Rail-mounted gantry cranes are designed to move along fixed rails installed on the ground. These cranes are widely used in container terminals, steel plants, and industrial facilities where heavy, repetitive, and linear material handling is required.

2.1 Structure and Components

The traveling mechanism of an RMG crane typically consists of:

-

Wheel bogies: Mounted at the base of the crane legs, these wheels run on steel rails and carry the entire load of the crane.

-

Rails: Fixed tracks installed along the crane’s operational path, usually made of high-strength steel to support heavy loads and prevent wear.

-

Drive motors and gearboxes: Powered by electric motors, these components propel the crane along the rails. Gearboxes adjust the torque and speed for smooth movement.

-

Braking system: Ensures the crane can stop precisely and safely under full load conditions. Modern systems often use electro-mechanical brakes or hydraulic brakes.

-

Guidance systems: Maintain alignment on the rails and prevent lateral movement or derailment.

2.2 Advantages of RMG Traveling Mechanisms

-

High load capacity: RMG cranes are ideal for extremely heavy loads, with capacities often exceeding 100 tons, as the rails provide stable support.

-

Precision movement: Rails ensure straight, predictable motion, which is critical when stacking containers, handling steel coils, or positioning precast components.

-

Durability: Steel rails and robust wheel assemblies withstand harsh operational conditions and high-frequency operations over many years.

-

Energy efficiency: Continuous rail contact reduces rolling resistance compared to tires, lowering energy consumption during movement.

2.3 Limitations

-

Fixed travel path: The crane can only move where rails are installed, limiting operational flexibility.

-

High infrastructure cost: Rail installation, maintenance, and leveling require significant upfront investment.

-

Time-consuming relocation: Moving an RMG crane to a new location involves extensive civil works and rail adjustments.

3. Rubber Tyred Gantry (RTG) Crane Traveling Mechanism

Rubber tyred gantry cranes, on the other hand, move on large rubber tires rather than fixed rails. These cranes are often found in container yards, bulk material handling areas, and flexible logistics terminals where mobility across large areas is critical.

3.1 Structure and Components

The traveling mechanism of an RTG crane includes:

-

Rubber tires: Mounted on the crane legs, these tires support the crane’s weight and allow it to move over concrete pads or paved surfaces. Tires can be pneumatic or solid, depending on load and terrain requirements.

-

Steering system: Allows maneuvering and alignment of the crane, often with multiple steering modes including crab steering, synchronized turning, and diagonal movement.

-

Drive motors and transmission: Electric or hybrid systems power the wheels. Some modern RTGs feature independent wheel drives for enhanced maneuverability.

-

Stabilizers or leveling system: Ensures safe operation by maintaining crane balance when lifting uneven loads.

-

Guidance and monitoring: GPS, laser guidance, or sensors help operators maintain proper alignment with stacking rows or transport paths.

3.2 Advantages of RTG Traveling Mechanisms

-

High mobility: RTG gantry cranes can travel across large areas without fixed rails, making them ideal for expanding or changing yard layouts.

-

Flexibility: They can access areas where rails cannot be installed, including temporary storage yards or uneven surfaces.

-

Lower infrastructure cost: There is no need for rail tracks, reducing installation and civil engineering expenses.

-

Multiple steering modes: Operators can adjust the crane’s movement to navigate tight spaces, avoid obstacles, or optimize stacking patterns.

3.3 Limitations

-

Lower load capacity compared to RMGs: Rubber tires have limits on weight they can safely bear, especially for extremely heavy loads.

-

Surface dependency: Operation requires smooth, well-maintained concrete pads; rough or uneven surfaces can reduce stability.

-

Higher maintenance: Tires wear faster than steel wheels, and steering systems require frequent checks and adjustments.

-

Energy consumption: Rolling resistance of rubber tires is higher, which can lead to increased energy use for frequent or long-distance travel.

4. Key Differences Between RMG and RTG Traveling Mechanisms

| Feature | Rail-Mounted Gantry (RMG) | Rubber Tyred Gantry (RTG) |

|---|---|---|

| Travel path | Fixed rails | Free on flat surfaces |

| Load capacity | Very high (up to 1,000+ tons for heavy industrial applications) | Moderate to high (usually below 150 tons for standard designs) |

| Mobility | Limited | Flexible and highly maneuverable |

| Installation cost | High (rails, leveling, foundation) | Lower (paved pads suffice) |

| Maintenance | Lower rolling wear; less frequent inspections | Higher tire wear; steering and alignment require regular checks |

| Precision | Excellent linear accuracy | Moderate; relies on guidance systems for positioning |

| Energy efficiency | Higher due to low rolling resistance | Lower due to tire friction |

| Ideal applications | Container terminals with fixed lanes, steel mills, precast plants | Flexible container yards, bulk material handling areas, temporary storage sites |

5. Applications and Considerations

When selecting between RMG and RTG traveling mechanisms, several operational factors must be considered:

-

Load requirements: For ultra-heavy lifting and stacking of standardized materials, RMG cranes are preferable. RTG cranes suit medium to heavy loads where operational flexibility is essential.

-

Operational area: If the crane must cover a large, adjustable yard or travel between multiple storage zones, RTG cranes are ideal. For long, narrow operational lanes, RMG cranes are more efficient.

-

Infrastructure investment: Rail-mounted systems require more civil engineering upfront, while RTG cranes can operate on existing concrete pads with minimal preparation.

-

Maintenance capacity: Facilities with robust maintenance teams may manage RTG tire wear and steering upkeep effectively. Otherwise, the low-maintenance nature of RMG cranes can be a decisive factor.

-

Environmental and surface conditions: RMG cranes tolerate minor ground imperfections if rails are properly leveled. RTG cranes require high-quality surfaces to maintain stability under load.

6. Future Trends in Gantry Crane Traveling Mechanisms

Modern gantry crane designs increasingly integrate automation, sensors, and digital monitoring into traveling mechanisms. Both RMG and RTG cranes now feature:

-

Automated movement systems: GPS-guided or PLC-controlled travel for precise load placement.

-

Energy recovery systems: Regenerative braking reduces power consumption.

-

Condition monitoring: Sensors track wheel, motor, and steering wear to predict maintenance needs.

-

Hybrid power options: Especially for RTG cranes, combining diesel and electric drives improves efficiency and reduces emissions.

The choice between rail-mounted and rubber-tyred systems is also evolving. Some facilities adopt hybrid solutions, using RMG cranes on fixed lanes for heavy loads while RTG cranes handle flexible, temporary storage areas, achieving both precision and adaptability.

Conclusion

The traveling mechanism is a cornerstone of gantry crane performance, influencing load capacity, operational flexibility, maintenance requirements, and overall productivity. Rail-mounted gantry (RMG) cranes excel in high-capacity, precise, and linear operations, making them ideal for container terminals, steel mills, and industrial production lines. Rubber tyred gantry (RTG) cranes, with their mobility and flexible steering options, suit dynamic yard environments where layout adjustments or multi-directional access is required.

Selecting the appropriate traveling mechanism requires a comprehensive understanding of load requirements, operational area, infrastructure investment, and maintenance capabilities. As gantry crane technology continues to evolve, integrating digital monitoring, automation, and hybrid mobility systems will further enhance the efficiency and versatility of both RMG and RTG cranes, ensuring that these essential machines remain at the heart of modern material handling operations.